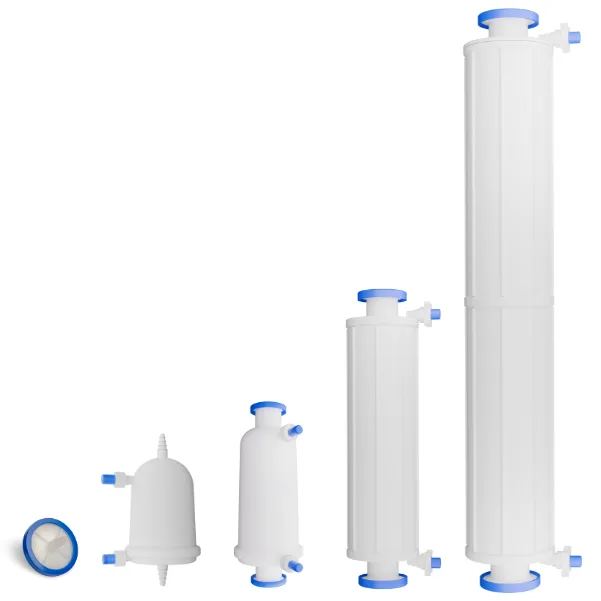

PES Capsule Filters

The PoreCap® series of PES capsule filters are ready-to-use sterile grade filtration devices available in 0.1µm and 0.22µm, and different sizes as per requirements. 0.45µm is for bioburden and particulate reduction.

With our advanced PES (Polyethersulfone) Membrane, these filters guarantee optimal bacterial retention and are a go-to choice for filtration of vaccines, injectables, API buffers, water for injections, beverages and lab water purification.

Manufactured in-house in ISO Classified cleanrooms, these devices incorporate highly efficient sterilizing grade Asymmetric Polyethersulfone Membranes safely placed inside a Polypropylene housing.

Crafted with precision & expertise, the PoreCap® PES capsule filters are easy to install & use as they eliminate the need to clean and validate the stainless-steel housing separately.

Membrane Characteristics: Each PoreCap® PES Capsule filter incorporates our high throughput hydrophilic PES membrane that offers excellent chemical compatibility and withstands a wide pH range. Available in single layer or dual layer options, these are absolute retention filters and offer excellent contaminant removal capacity.

Materials of Construction

| Membrane: | Polyethersulfone |

| Housing: | Polypropylene |

| Core: | Polypropylene |

| End Connections: | Polypropylene |

| Rings: | Silicone (Only with 1/4" MNPT) |

Operational Parameters

| Max Temp: | 80 °C @ ≤ 2 Kg/cm² |

| Max Pressure: | 3.5 Kg/cm² @ 25 °C for forward, 0.7 Kg/cm² @ 25 °C for reverse |

| Autoclave: | 30 autoclave cycles @125 °C |

Bubble Point

| 0.10µm: | ≥ 1931 mbar (28 psi) (50% IPA) |

| 0.22µm: | ≥ 3447 mbar (50 psi) (with water wetted) |

| 0.45µm: | ≥ 2069 mbar (30 psi) (with water wetted) |

Max Air Diffusion Flow (for 10″ Capsule)

| 0.10µm: | ≤ 30 mL/min @ 3447 mbar (50 psi) (with water wetted) |

| 0.22µm: | ≤ 30 mL/min @ 2482 mbar (36 psi) (with water wetted) |

| 0.45µm: | ≤ 35 mL/min @ 1655 mbar (24 psi) (with water wetted) |

Microbial Retention

| 0.22µm: | LRV > 7 for Brevundimonas Diminuta |

| 0.45µm: | LRV > 7 for Serratia marcescens |

Sterilization

| ETO: | Yes |

| Gamma: | Yes |

| Non-sterile: | Yes |

| Non-sterile (Gamma strerilizable): | Yes |

Regulatory Compliance

| Endotoxin releasing: | <0.25 EU/mL as determined by the LAL test |

| Particle release: | Meets the requirements of WFI set by USP |

| Non-fiber releasing: | Meets the criteria for a non-fiber releasing filter as per USP |

| Material toxicity: | All components meet the requirements of the USP Reactivity Test for Class VI Plastics Filters meet the requirements of USP Biological Reactivity Tests in Vitro Cytotoxicity. Filters meet the requirements of USP Biological Reactivity Tests in Vitro Cytotoxicity |

| Bacterial challenge test: | Filters with the claim passed the bacterial challenge testing using Brevundimonas diminuta (ATCC 19146) at a minimum challenge concentration 1x10⁷ CFU/cm² (0.22 µm) per ASTM F838-20. |

| Extractables: | Tested according to BioPhorum Operations Group (BPOG) guideline. Report is available upon request. |

| Indirect food additive: | Meets the FDA Indirect Food Additive requirements cited in 21 CFR 177.1520 |

| Quality: | Manufactured in accordance with ISO 9001 and ISO 13485 certified quality management system |

Drug Specific Filter Validation Services

Through, nSure Validation Services, we offer a complete range of filter validation services to qualify your molecules with our Filters in accordance with the requirements listed in PDA TR#26 and in compliance with international regulatory bodies such as USFDA and EU GMP.