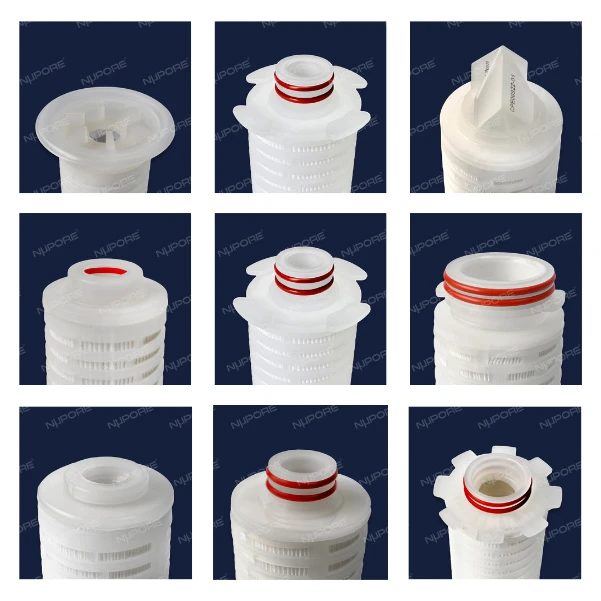

PVDF Cartridge Filters

PVDF cartridge filters are sterile grade filtration devices recommended for final filtration and high protein recovery applications such as filtration of vaccines, antibodies, plasma products and hormonal injectables etc.

Assembled with our absolute rated PVDF (polyvinylidene fluoride) membranes, these PVDF cartridge filters offer low protein binding and are designed to withstand multiple steam-in-place cycles.

Manufactured in-house in ISO Class 8 cleanrooms and designed with a unique construction structure & an advanced pleating technology, each PVDF cartridge filter is integrity tested.

Membrane Characteristics: The NuCart® PVDF Cartridge Filters incorporate hydrophilic PVDF membrane that offers high flow rates, a high number of sterilization cycles, and ultra-low protein binding.

Materials of Construction

| Membrane: | Polyvinylidene fluoride |

| Housing: | Polypropylene |

| Core: | Polypropylene |

| End Connections:: | Polypropylene |

Operational Parameters

| Max Temp: | 80 °C @ ≤ 2 Kg/cm² |

| Max Pressure: | 3.5 Kg/cm² @ 25 °C for forward, 0.7 Kg/cm² @ 25 °C for reverse |

| Autoclavable: | 25 autoclave cycles @125°C |

Bubble Point

| 0.22µm: | ≥ 3447 mbar (50 psi) (with water wetted) |

| 0.45µm: | ≥ 2069 mbar (30 psi) (with water wetted) |

Max Air Diffusion Flow (for 10″ Cartridge)

| 0.22µm: | ≤ 20 mL/min @ 2482 mbar (36 psi) (with water wetted) |

| 0.45µm: | ≤ 20 mL/min @ 1517 mbar (22 psi) (with water wetted) |

Microbial Retention

| 0.22µm: | LRV > 7 for Brevundimonas Diminuta |

| 0.45µm: | LRV > 7 for Serratia marcescens |

Regulatory Compliance

| Endotoxin releasing: | <0.25 EU/mL as determined by the LAL test |

| Particle release: | Meets the requirements of WFI set by USP |

| Non-fiber releasing: | Meets the criteria for a non-fiber releasing filter as per USP |

| Material toxicity: | All components meet the requirements of the USP Reactivity Test for Class VI Plastics Filters meet the requirements of USP Biological Reactivity Tests in Vitro Cytotoxicity |

| Bacterial challenge test: | Filters with the claim passed the bacterial challenge testing using Brevundimonas diminuta (ATCC 19146) at a minimum challenge concentration 1x10⁷ CFU/cm² (0.22 µm) per ASTM F838-20. |

| Extractables: | Tested according to BioPhorum Operations Group (BPOG) guideline. Report is available upon request. |

| Quality: | Manufactured in accordance with ISO 9001 and ISO 13485 certified quality management system |

Drug Specific Filter Validation Services

Through, nSure Validation Services, we offer a complete range of filter validation services to qualify your molecules with our Filters in accordance with the requirements listed in PDA TR#26 and in compliance with international regulatory bodies such as USFDA and EU GMP.