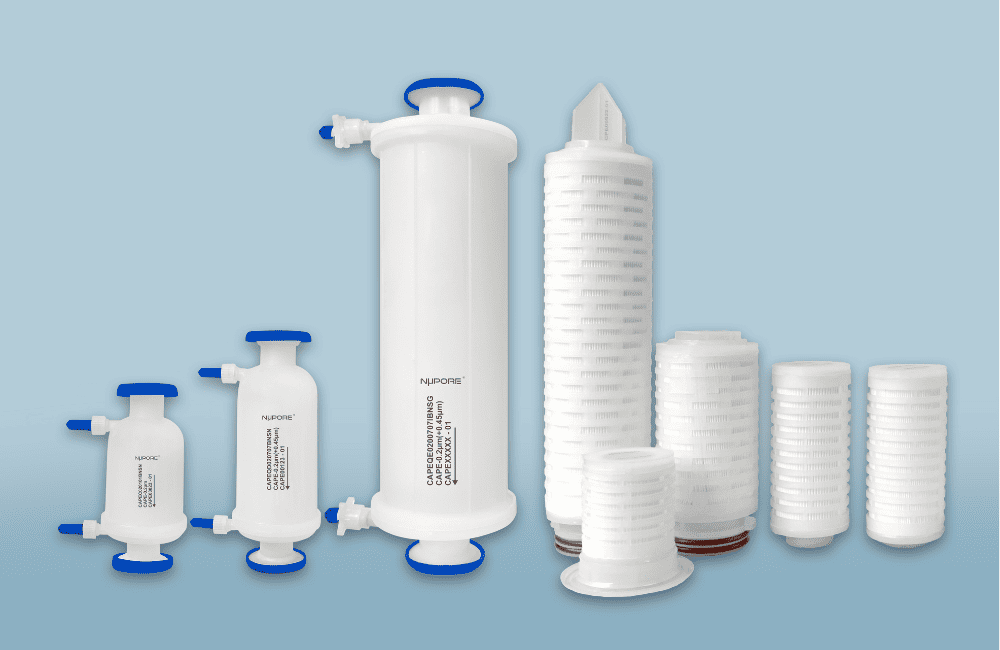

Polypropylene Cartridge Filters

Nupore Polypropylene Cartridge Filters are available in a wide range of pore sizes ranging from 0.2µm to 50µm and are especially designed and developed for high particle retention, dirt holding and pre-to-final filtration applications.

These filters are available in 3-40 inch sizes and offers surface filtration as well as depth filtration for better throughput.

These are tested for retention efficiency, integrity and flow rate, and validated for heat stability, beta ratio, fibre particle release and biosafety.

Membrane Characteristics: Our Polypropylene Cartridge Filters incorporate high performance single layer or multilayer Polypropylene membranes which are best suited for turbidity reduction resulting in optimal protection of final sterile grade filters

APPLICATIONS

- Biological prefiltration applications

- Protection of final membrane filters

- Particulate/ coarse removal

- Early clarification in production of sterile liquids

- Prefiltration of water, chemicals and solvents

Microbial Validation

Validated as per the ASTM F 838-05 requirements for determining bacterial retention of membrane filters used for liquid filtration

FDA Compliant

Biosafety & Extractables

Integrity Tested

Global Manufacturing Standards

Easy Identification & Tracking

Each filter unit has a unique identification marking which enables quick backtracking

100% Integrity Tested

Guaranteed Specification as per Actual Data

Non Leachable

Ergonomically Designed & Developed

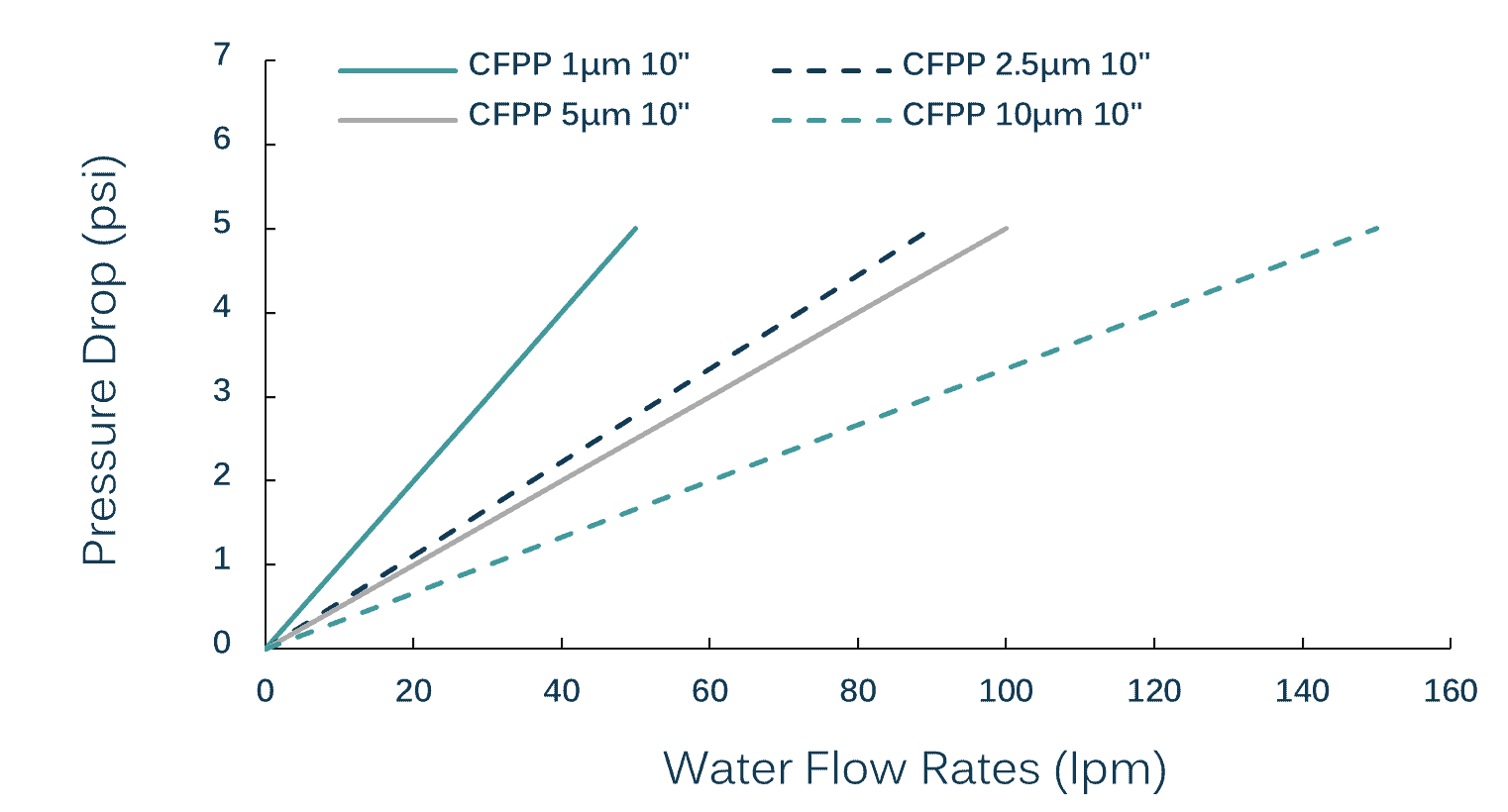

TECHNICAL SPECIFICATIONS

Polypropylene Cartridge Filters

| Materials of Construction | ||

| Membrane: | Polypropylene | |

| Housing: | Polypropylene | |

| Core: | Polypropylene | |

| End Connections: | Polypropylene | |

| Rings: | Silicone, EPDM, Viton, Encapsulated PTFE, Synthetic Rubber | |

| Operational Parameters | ||

| Max Temp | 80 °C @ ≤ 2 Kg/cm2 | |

| Max Pressure | 3.5kg/cm2 @ 25 °C for forward | |

| 0.7kg/cm2 @ 25 °C for reverse |

| Effective Filtration Area: | |||||

| Length: | 1″ | 2″ | 5″ | 8″ | 10″ |

| Area: | 0.025m2 | 0.05m2 | 0.10m2 | 0.20m2 | 0.60m2 |

QUALITY ASSURANCE & VALIDATION

All filters are 100% integrity tested and are developed and manufactured under an ISO 9001:2015 certified Quality Management System and designed to be used in cGMP compliant processes.

Microbial Validation

All our Cartridge and Capsule filters are validated as per the ASTM F 838 requirements for determining bacterial retention of sterilizing grade filters

Certificate of Quality

All our products are delivered along with a Certificate of Quality (CoQ) mentioning the materials of construction and testing & quality parameters

Throughput Studies

We help you select the perfect mix of prefilters and final filters by performing small scale filtration and determining the filtration area to reach your desired throughput

Extractables & Leachables

Our Extractables & Leachables testing study is a highly effective way to quantify and assess risks associated with leachable impurities from filters

Why Choose Us

With our extensive knowledge in membrane filtration and a wide range of products available at every stage of the process, along with our exceptional customer service, we are able to establish ourselves as the preferred partner.

Extensive Product Portfolio

At Nupore, we offer a wide range of filtration for your process requirements. Use our quick guide to land instantly at the product of your choice

Proven Membrane Technology

Fast Shipping

Talk To Us

Need assistance choosing the right product for your application, or have a question about ordering from us? Connect with an Expert